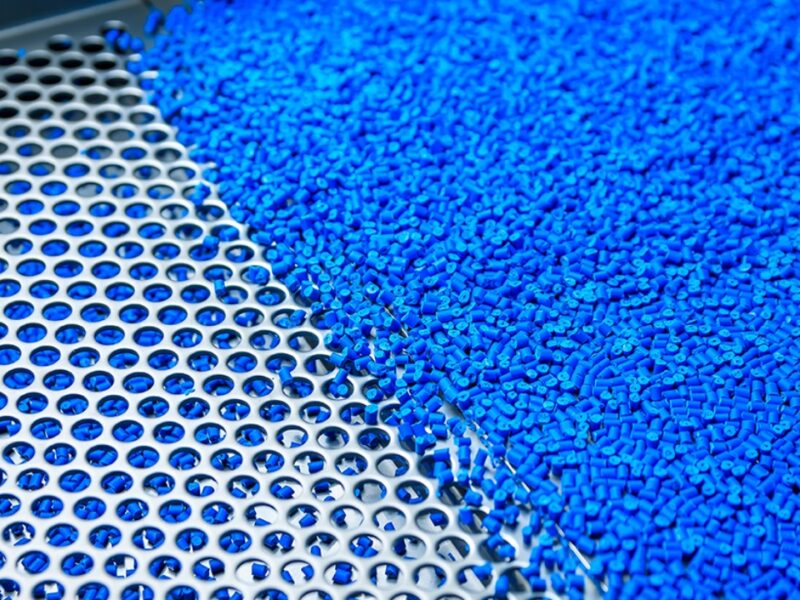

Plastic granules for injection moulding

High quality injection moulding starts with good plastic raw materials. Q Plastics has experience in its own injection moulding plant, and with a rich network in the world of plastics, we can supply your company with the best granules and (re)granulates. We can also provide personal advice and guidance.

Recycled granulates of

the highest quality.

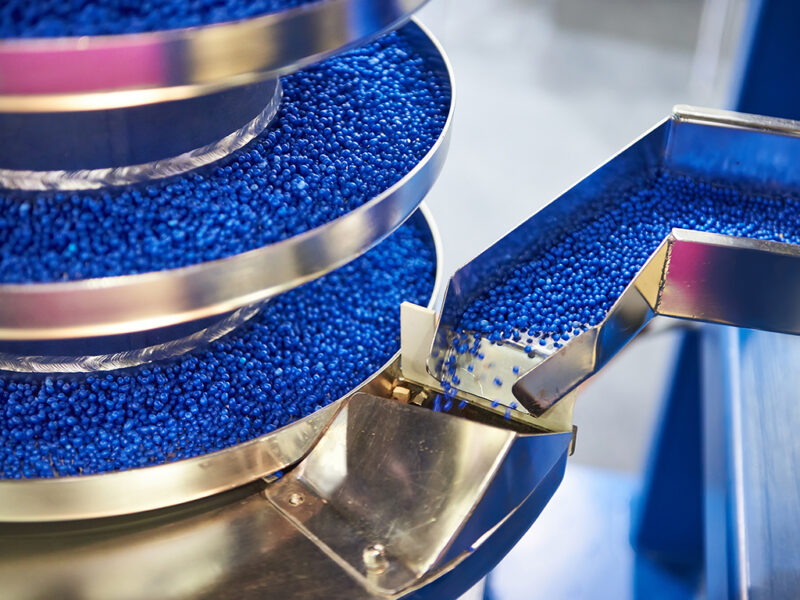

The prices of raw material for plastic have risen sharply in recent years. This will have a direct impact on the pricing of plastic products. Q Plastics actively looks for recycled granulates for use in your injection moulding applications. You get the same quality for a lower budget.

Our granulates

Stock offers

Q Plastics has a wide range of various granulates. The latest stock offers can be found here. Can't find what you're looking for? Contact us, we can certainly help you.

A suitable granulate for

every application

Every machine park and product requires a different approach. Q Plastics uses its broad experience to find the perfect match between raw material and end result.

- Prime granules

- Off-spec

- Mill material

- Regranulates

an urgent question?

News

What is the difference between PE and PP? What should you pay attention to when switching to recycled plastics? And what is the most suitable raw material for each application?

Contact us, we will be happy to assist.